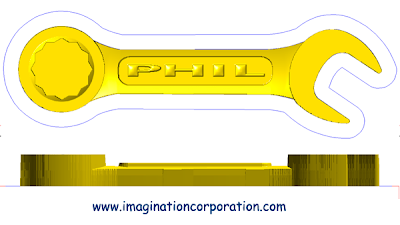

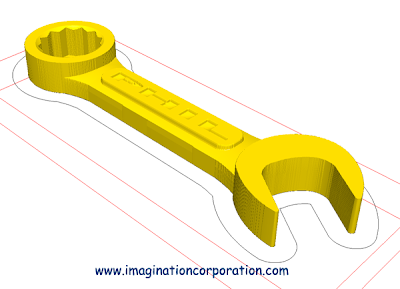

The next name plaque was for someone I knew quite well - the technician from MultiCam. He has only been to our shop once or twice but I got to know Phil pretty good when I was doing the work for their shop. I surmised Phil will most likely hang his name plaque in his office. He was eyeballing my large display wrench during the open house so I figured I'd make one for him. I used a wrench out of my tool box as reference when I created the vectors. They were done in three sections because they needed to be different heights and shapes.

I created the reliefs individually and merged them together before going to the next step. Then the raised name plate as created as a separate relief and Phil's name was embossed using the subtract from relief tool - all in EnRoute.

Then I used the subtract from relief tool once more in the dome mode to create the beveled dimple in the box end of the relief.

Then I created a zero height relief of the eight sided box end. This was merged with the wrench using merge lowest function.

As simple as that the wrench file was finished and ready to tool path. I'll be adding a little texture with the die grinder when the routing is done to make it look like it has been used.

This is a cool display piece that would make a great gift for anyone with a shop. It doesn't take much material and is done in a hurry. To make a full wrench just mirror it and then add the name to both sides. That way one side isn't backwards.

-dan